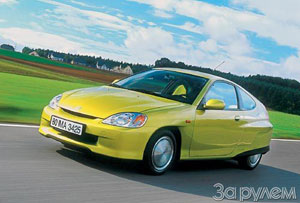

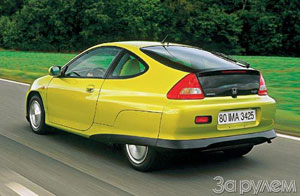

Test drive Honda Insight 1999 - 2006 hatchback

Selection fruits

It will take a lot of time, while cars with zero exhaust, for example, hydrogen cars will finally replace their ancestors with gasoline and diesel engines. In the meantime, the so -called hybrids are produced. A pair with the internal combustion engine works an electric motor: it gives an increase in power and torque, helps to save fuel and significantly improves environmental indicators.The number of such models is growing. In our virtual duel, two founders of the hybrid movement came together. Toyota Prius lives in the second generation the first version debuted in 1997, becoming a pioneer of serial hybridization in the world.

Two years later, Honda Insight came out. The concepts of Japanese machines are generally similar, but implemented in different ways.

In the kingdom of internal combustion

A one and a half -liter Toyota gasoline engine, designed specifically for the Prius, operates in the Atkinson cycle. The geometric degree of compression of 13.5 compared to many engines with the traditional Otto cycle is very high. In order to prevent destructive detonation, the intake valve is closed much later than the lower dead point, spitting out part of the fresh charge back into the intake manifold. It turns out that to compress the mixture, the piston uses only part of its stroke, and all on the stact of expansion. This is beneficial in terms of completeness of combustion of the mixture and allows you to get the best environmental indicators and economy.

A one and a half -liter Toyota gasoline engine, designed specifically for the Prius, operates in the Atkinson cycle. The geometric degree of compression of 13.5 compared to many engines with the traditional Otto cycle is very high. In order to prevent destructive detonation, the intake valve is closed much later than the lower dead point, spitting out part of the fresh charge back into the intake manifold. It turns out that to compress the mixture, the piston uses only part of its stroke, and all on the stact of expansion. This is beneficial in terms of completeness of combustion of the mixture and allows you to get the best environmental indicators and economy. The gas distribution phases are regulated by the VVT \u200b\u200bsystem known for other Toyota engines. The control unit, depending on the load and revolutions, calculates the optimal time of the opening and closing of the valves and gives the command to hydraulic rotary devices that rotate the camshafts. For the Prius engine, the designers facilitated the pistons as much as possible, selected valves springs with optimal rigidity, installed the release system with minimal counterfeit. Most of the constructive solutions, of course, passed from the predecessor of the first generation motor. A new engine is controlled by a computer with a 32-bit processor.

Honda, developing an insight motor, also put fuel savings and ecology at the forefront.

The designers tried not only to find high -tech materials in order to reduce the total weight of the unit and friction loss, but also to reduce the number of details. For example, a multi -valve structure (four per cylinder) costs one camshaft in the bed of the block head. By the way, to reduce friction on the rockers, the rollers were installed, and an antifriction coating was applied to the piston skirts. The developers say that in this way, power losses were reduced by 30%. To facilitate the structure, the oil crankcase, as well as the control housings, was made of magnesium alloy, which is about a third lighter than aluminum. Some engine details, in particular the intake manifold and block of the block head, are made of composite materials.

The designers tried not only to find high -tech materials in order to reduce the total weight of the unit and friction loss, but also to reduce the number of details. For example, a multi -valve structure (four per cylinder) costs one camshaft in the bed of the block head. By the way, to reduce friction on the rockers, the rollers were installed, and an antifriction coating was applied to the piston skirts. The developers say that in this way, power losses were reduced by 30%. To facilitate the structure, the oil crankcase, as well as the control housings, was made of magnesium alloy, which is about a third lighter than aluminum. Some engine details, in particular the intake manifold and block of the block head, are made of composite materials. The dynamic characteristics of the Honda engine improves the VTEC phase adjustment system. Many curious decisions were forced to implement in iron and ecology. For example, the exhaust manifold is combined with the head of the block. The worked out gases warm the neutralizer faster, which means that with cold start, harmful emissions are less polluted in the atmosphere. The indispensable design allowed to win in weight. In addition, to save fuel in low and medium -power modes, the engine operates on depleted mixtures, during the combustion of which nitrogen oxides are released. To capture their business of an additional Nox-neutralizer.

Plus kilowatts

Plus kilowatts A 57 kW gasoline engine alone could not provide worthy dynamic characteristics of the Prius. A 50-kilowatt electric motor of alternating current works with it. Unlike the first generation hybrid installation, here the electric engine is no longer auxiliary, but a dominant role. The car is touched on the electric trough even with quite dynamic acceleration. The gasoline unit joins the work much later. At medium speeds and in some modes, mainly when the internal combustion engine operates in the non -optimal speed range, the electric motor also assumes the main load.

It is curious that the driver, by pressing the EV (Electric Vehicle Electric Car) button) on the instrument panel, can set the mode in which the internal combustion engine will not turn on at all. With fully charged batteries, the priest passes only on electricity up to 2 km at a speed of not more than 50 km/h.

The gearboxes as such have no hybrid Toyota. Electric and gasoline engines, as well as the starter-generator are connected by planetary transmission, the moment from which through the gearbox (4.11: 1 ratio) goes to wheels. The control unit coordinates the transmission of the transmission, giving commands to the executive mechanisms of the planetary transmission, inhibiting the necessary gear.

The gearboxes as such have no hybrid Toyota. Electric and gasoline engines, as well as the starter-generator are connected by planetary transmission, the moment from which through the gearbox (4.11: 1 ratio) goes to wheels. The control unit coordinates the transmission of the transmission, giving commands to the executive mechanisms of the planetary transmission, inhibiting the necessary gear. Honda adheres to a different scheme. An electric motor with a capacity of 7 kW only helps the internal combustion engine and does not work alone. Like the Prius, at the stops, the gasoline engine stalls, without wasting fuel and without polluting the atmosphere. To let it down, just squeeze the clutch and turn on the first gear.

Honda's bronnote electric motor in Honda is more compact and easier than Toyotovsky. A narrow 60-mm housing is installed between the engine and the gearbox (the choice of a mechanical five-speed or variator). At acceleration, the electric motor twists the crankshaft, and when braking acts as a generator, converting mechanical energy into an electric one and giving the current of a metal -hydrid battery located in the floor behind the seats. In terms of capacity and dimensions, it is smaller than that of the Prius. But the Toyota electric motor is several times more powerful. But, unlike the prieus, when failing of the electric motor, you can go on an insite on a gasoline engine.

Ground savings

One of the main tasks set by the developers of hybrids to make a car either in appearance or in dynamic qualities not different from normal machines. The hybrid should be released by friendliness to the environment and a modest fuel consumption. According to Honda calculations, about 65% of saved gasoline accounts for a hybrid unit. Where are the other 35%?

Insight developers tried to facilitate the car as easier as possible. They were able to remove extra pounds not only from the compact power unit. The double body is aluminum, with the exception of some parts from almost weightless composite materials. The steel dress would be almost 40% heavier.

Toyota engineers also understood: excess weight in vain lost gasoline liters. Therefore, a body made of high -strength lightweight steel, aluminum and composite parts made a hybrid. Of course, Toyota could not achieve the phenomenal results of Honda. However, do not forget that the insight is smaller, and there are only two places in the cabin, and five will sit down in the prose.

In the development of bodies, of course, great attention was paid to aerodynamics. They licked everything that is possible, and the bottoms of the cars were made absolutely flat. On the insite, even closed the rear wheels with shields. Result: SX Honda 0.25, Toyota 0.26.

In the development of bodies, of course, great attention was paid to aerodynamics. They licked everything that is possible, and the bottoms of the cars were made absolutely flat. On the insite, even closed the rear wheels with shields. Result: SX Honda 0.25, Toyota 0.26. Narrow tires with low rolling resistance help to save gasoline. Particularly unusual is the size of the prie shoe. Hybrid steering amplifiers are electric. They do not take excess forces from the engine and do not waste idle precious fuel. For the same reason, the compressor of the air conditioner is also given by an electric motor.

It's time to summarize the first stage of hybridization. From a technical point of view, Toyota is more interesting. No wonder 300 patents were issued during the development of the first bond, and the second 530. Some large firms have already bought a license from Toyota. Honda is strong in another hybrid components are more compact and easy.

Both concepts are viable. The production of bonds is growing, and Honda has already made several models with hybrid installations. Obviously, the union of electricity and gasoline will grow stronger. And the volume of the fuel tank will be interested in us no more than the battery capacity.

Maxim Sachkov

Source: The magazine "Driving"